A trommel is a rotating drum and it is mainly used to separate materials by size. It is used in many industry sectors, mostly in construction and mining and also in solid field waste and gravel processing. There are different trommel models available on the market. Click here to learn more about trommel.

Tuesday, August 26, 2014

What Is A Trommel

Monday, August 25, 2014

Types Of Mining Equipment

Durable, powerful and highly efficient mining equipment is crucial for every mining operation. There are different types of mining equipment on the market, designed and used for specific mining applications. Coal mining, oil and gas extraction, ore and metal mining, non metal mining etc, these mining sectors require specific mining equipment to be used. Click here to learn more about the mining equipment used at the mining sites.

Labels:

mining equipment,

mining machinery,

mining machines

Location:

Australia

Thursday, August 21, 2014

The Purpose Of Rock Breaker

Rock breaker is a very efficient tool for contractors that deal with large and heavy objects. It is able to crush almost any rock on the Earth and so benefit the contractors to remain productive and efficient. Click here to find out the purpose of rock breaker.

Labels:

attachments,

excavator attachments,

rock breaker

Location:

Australia

The Unique Franna Cranes

The most popular and mostly used crane

in Australia is the Franna crane. Firstly known as pick and carry

crane and after as Franna crane, with is't versatility is used in

variety of plants, construction job sites, mines and other. Click here to read why Franna cranes are so unique.

Labels:

construction equipment,

crane,

franna,

Franna cranes

Location:

Australia

Wednesday, August 20, 2014

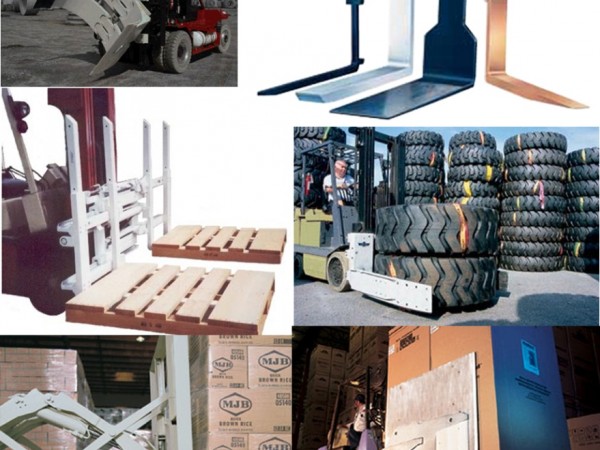

Simple Guide For Safe Forklift Attachment Operation

Forklift attachments significantly increase the versatility and flexibility of the forklifts, allowing any operator maximized productivity at lower operating costs. However, the safety of the operators may be impacted if not treated properly and safely. Click here for a simple guide for safe forklift attachments operation.

Labels:

attachments,

forklift attachments,

forklifts

Location:

Australia

Monday, August 18, 2014

Safety Precautions For Mini Crane Operators

The on-going trend in construction industry is replacing the large and high cost-efficient cranes with small cranes. The small cranes are increasingly becoming popular among the contractors, since they have the same possibilities as the large cranes, while operating at much lower costs. Compact-sized and lightweight, the mini cranes are exceptionally maneuverable and versatile, so they can operate in the narrowest spaces.In terms of operating, there are no significant differences, because the mini cranes can be just as dangerous as the large cranes. However, the small cranes are very often underestimated and considered as not as dangerous as the large cranes. When it comes to operating mini cranes, you need to follow few simple and helpful safety precautions in order to ensure your safety and the safety of nearby workers and equipment. The following safety precautions are must-know for all operators of mini cranes.

Before Operation:

- Acquire a proper protective gear and make sure you to wear it during operation. Gloves, steel-capped boots and helmet are the most common pieces of protective equipment.

- You need to inspect your mini crane before each operation and carry out regular quick inspections during use. If there is a damaged or missing part, you need to remove your crane from use and take it to crane service.

- Before refueling or changing lubricants, you need to make sure the engine is off. Also, you should not have a fire source with you when undertaking it.

During Operation:

- When operating a small crane, you need to make sure that the outriggers (if it has) are properly extended and positioned.

- When making a sharp turn or drive on an uneven ground, you need to operate your mini crane as slow as possible. The same applies when driving over a bump.

- Never run small cranes over a bumpy area, rough solid rocky area, sharp-edged area, waste materials, steel bars, scrap metals, etc.

- Do not park your mini crane over a grassed or strawed area, because the heat of the exhaust pipe or fumes can cause a fire.

After Operation:

- Turn the engine of your crane off and remove if there is any dirt or dust on the machine. Pay the most attention on the electrical wiring, battery and all components related to the engine, in order to avoid a fire.

- After operation, the small cranes require to be covered and stored properly, far from the touch of unauthorized persons. Keep in mind to cover your mini crane when the heated areas are cooled.

By following these safety precautions, you will operate and maintain your mini crane properly and safely. Also, you can recommend these tips to other operators who makes mistakes when operating mini cranes.

Labels:

construction equipment,

mini cranes,

small cranes

Location:

Australia

Friday, August 15, 2014

Guide On Safe Use Of Excavators

Excavators are some of the most used equipment for a variety of applications on construction job sites. However, they need to be properly and safely used, because otherwise, they can represent a huge threat for the operators and other workers. Every year, there are many accidents in Australia that include excavators, with terrible results, including serious workers and equipment damages and even deaths. The operators of excavators have huge responsibilities and they need to undertake all kinds of safety precautions to remain safe on job site. Here is a short guide on safe use of excavators.

Labels:

equipment,

excavators,

machinery,

mining machines

Location:

Australia

Subscribe to:

Posts (Atom)